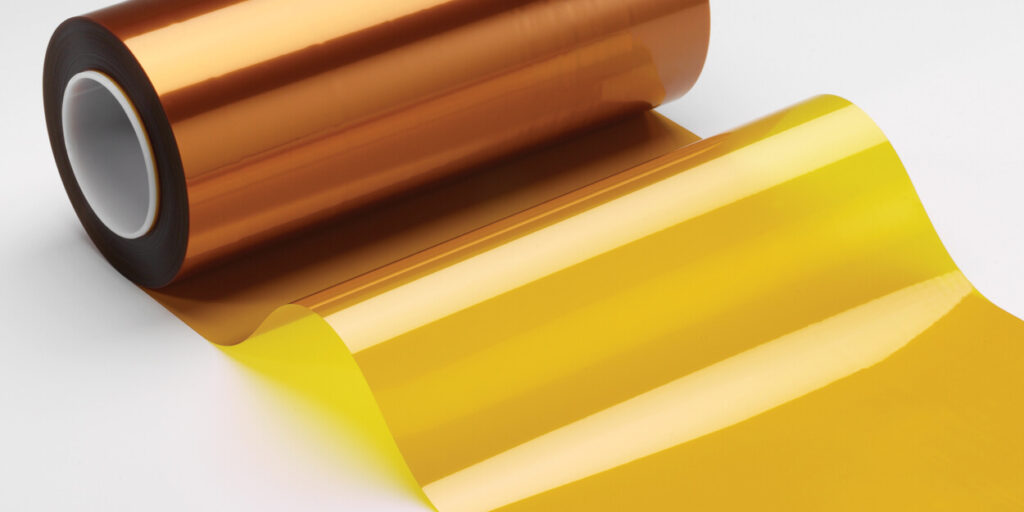

polyimide for specialty fabricated products

Custom high performance polymer Films

APICAL® Polyimide Film Is the Right Choice.

Custom High Performance Polymer Films with APICAL® Polyimide

APICAL® Polyimide: The Right Choice for Specialty Fabricated Products

APICAL® Polyimide Film is used in a wide range of unusual applications due to its unique high and low operating temperature capability. These applications include bar code labels, speaker coils, spiral wrapped tubing, gaskets and diaphragms, aircraft shim stock, space blankets, nuclear linear accelerator insulation, carrier and transport belts, and sensors. The versatility of APICAL® Polyimide Film means there is no end to the new applications that are found every day for this exceptional high performance polymer film, making it the premier polyimide for specialty fabricated products.

Versatile Applications for Polyimide for Specialty Fabricated Products

The unique properties of APICAL® Polyimide Film make it suitable for a wide array of specialty fabricated products. Whether it’s in the demanding environment of a nuclear linear accelerator or the delicate requirements of a bar code label, APICAL® Polyimide Film delivers exceptional performance. Its ability to function effectively in both extremely high and low temperatures is a key reason why it is the preferred polyimide for specialty fabricated products.

Primary Film Properties for High-End Applications

The primary film properties that make APICAL® Polyimide the material of choice in high-end applications include:

- No Melt Point and Flame Resistance: APICAL® Polyimide Film has no melt point and will not sustain or propagate flame (UL 94-VO rating), making it ideal for safety-critical applications.

- Wide Operating Temperature Range: It can be used in applications from -269°C to 400°C while still maintaining mechanical and electrical integrity, which is crucial for specialty fabricated products.

- Excellent Mechanical Properties: High abrasion and cut-through resistance ensure durability and longevity in demanding environments.

- Chemical Resistance: APICAL® Polyimide is resistant to most acids, solvents, lubricants, and hydrocarbons, though it is susceptible to degradation by strong bases.

- Superior Electrical Properties: High dielectric strength, good dielectric constant, and low dissipation factor make it an excellent insulator.

- High Thermal Dimensional Stability: Low shrinkage at elevated temperatures up to 400°C ensures stable performance.

- Adhesion to Various Adhesive Systems: Good adhesion to a wide range of adhesives, including silicones, acrylics, polyimides, FEP, PTFE, PFA, epoxies, and modified epoxies, and phenolics.

- High Radiation Resistance: Its ability to withstand radiation makes it suitable for nuclear and space applications.

- Excellent Flexural Durability: This ensures that the film can be flexed repeatedly without losing integrity.

Why Choose APICAL Polyimide For

Specialty Fabricated Products?

APICAL® Polyimide Film stands out as the ultimate polyimide for specialty fabricated products due to its superior properties and versatility. Its flame resistance, wide operating temperature range, excellent mechanical and electrical properties, chemical resistance, and high radiation resistance make it the material of choice for high-performance and demanding applications. Trust APICAL® Polyimide for all your specialty fabricated product needs to ensure unmatched performance and reliability.

Downloads

Applications

Ask The Engineers

Custom high performance polymer Films

APICAL® Polyimide Film Is the Right Choice.

- No melt point, and will not sustain or propagate flame (UL” 94-VO rating).

- Can be used in applications from -269°C to 400°C while still maintaining mechanical and electrical integrity.

- Excellent mechanical properties, high abrasion and cut-through resistance.

- Excellent chemical resistance to most acids, solvents, lubricants, and hydrocarbons. (It is, however, susceptible to degradation by strong bases).

- Excellent electrical properties (high dielectric strength, good dielectric constant, and low dissipation factor).

- High thermal dimensional stability, low shrinkage at elevated temperatures to 400°C.

- Good adhesion to a wide range of adhesive systems (e.g. silicons, acrylics, polyimides, FEP, PTFE, PFA, epoxies and modified epoxies, phenolics).

- High radiation resistance.

- Excellent flexural durability.

Downloads

- Technical Data Sheet - 50AV

- Technical Data Sheet - 75AV

- Technical Data Sheet - 100AV

- Technical Data Sheet - 200AV

- Technical Data Sheet - 300AV

- Technical Data Sheet - 500AV