Maintaining Polyimide Film Appearance and Performance

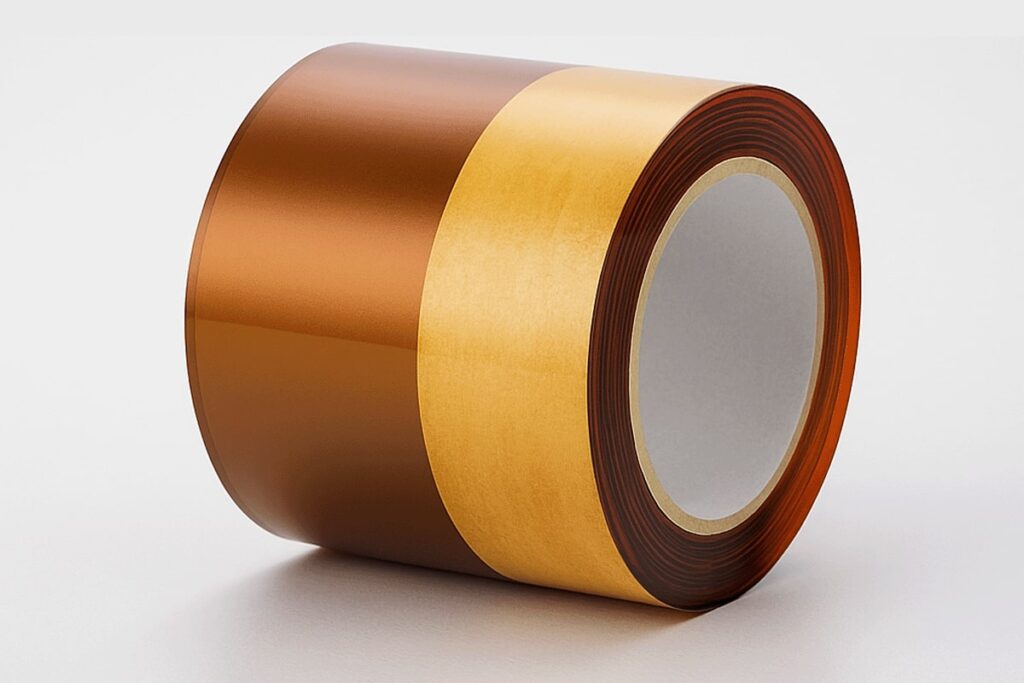

Maintaining the quality of APICAL® Polyimide Film is important. This material is widely valued for its ability to withstand extreme conditions in various industries, from aerospace to electronics. It plays a crucial role in making sure products are efficient and reliable. However, like many materials, APICAL® Polyimide Film can suffer from discoloration due to exposure to ultraviolet (UV) light. This change in appearance might not seem like a big deal at first, but it can affect the film’s performance over time. Understanding how this discoloration happens and taking steps to correct it can keep your films in top shape and preserve their functionality.

When polyimide films are exposed to UV rays, you might notice some fading or changes in color. But what exactly causes this to happen? The culprit is the breakdown of the film’s chemical bonds. UV light can lead to changes in the molecular structure of the film, making it less effective at doing its job. This means that products relying on this film might not operate as efficiently as they should. With a little bit of knowledge and precaution, though, you can minimize these effects and keep your film looking and performing well.

Understanding UV Discoloration

Discoloration in polyimide films due to UV exposure happens when the ultraviolet rays cause chemical bonds within the polymer structure to break down. Think of it like what happens to artwork left in direct sunlight; colors can fade and lose their original vibrancy. In the case of polyimide films, this fading is more than just a cosmetic issue. As the film’s molecular structure deteriorates, its insulating properties and ability to resist high temperatures might also get compromised.

Picture a windshield tinted to block harmful sunlight. If the tint weakens, it’s not just a visual problem—your car might heat up faster. Similarly, when APICAL® Polyimide Film discolors, its performance in specialized applications can diminish. Maintaining these films involves more than just surface appearances. Recognizing the signs of UV damage is a step towards maintaining product integrity and effectiveness.

Discoloration can sometimes be subtle, not immediately visible. You might only notice changes after prolonged exposure or specific light conditions. If left unchecked, the damage could progress, leading to more significant degradation. Being aware of these changes and understanding how to inhibit them through protective measures can make a substantial difference in maintaining the integrity of your polyimide films.

Preventative Measures

To keep your APICAL® Polyimide Film looking and functioning at its best, consider the following preventive steps:

- Proper Storage: Store your films in a cool, dark place. Avoid environments where they’ll be exposed to direct sunlight or high temperatures, which can accelerate degradation.

- Use of Protective Coatings: Apply coatings that can block or reduce UV light exposure. This extra layer acts like sunscreen for your films, shielding them from harmful rays.

- Environmental Controls: Maintain stable temperatures with minimal light exposure. Using UV filters on lights in storage areas can help reduce the ambient UV levels.

Implementing these strategies can help reduce discoloration and prolong the lifespan of your films. Being proactive with maintenance not only protects the film’s appearance but also ensures it continues to perform its intended role effectively, whether in an aircraft cabin or an electronic circuit. By taking these steps, you’re investing in the longevity and reliability of your materials.

Correcting Discoloration

If you notice discoloration, don’t worry; there are ways to address it. Start by determining the extent of the discoloration. If it’s just a surface change, a gentle cleaning might be enough. Use a soft, non-abrasive cloth with a mild cleaning agent specifically made for polyimide films. Avoid harsh chemicals that could harm the film’s sensitive layers. For more ingrained discoloration, consult a professional who understands the nuances of this type of material.

In cases where the film has reached a level of discoloration that affects its performance, consider whether replacing it is necessary. Sometimes, no amount of cleaning will bring back its original properties if the damage has penetrated too deeply. Deciding to replace rather than restore ensures safety and efficiency in use, especially in high-stakes environments like aerospace or electronics.

Assessing loss in quality due to discoloration isn’t always obvious. While surface repairs might seem okay, they might hide underlying issues that could compromise your materials. Always weigh the pros and cons of repair versus replacement to maintain the integrity of your applications.

Long-Term Maintenance Tips

Consistent checks and maintenance are great ways to extend the life of your films. Here’s a simple routine to get you started:

- Regular Inspections: Schedule routine checks, especially if your films are in environments with fluctuating exposure to light. Look for early signs of discoloration, like unexpected fading or spots. Checking these signs earlier means easier fixes and less risk.

- Scheduled Cleaning: Implement a regular, careful cleaning process using approved materials to help sustain the film’s original color and performance.

- Maintenance Records: Keep track of any cleaning or repairs. Documenting these actions can help identify patterns that might indicate systemic issues in storage or usage environments.

- Protective Measures: As soon as you spot potential wear, apply more protective coatings or revise your storage conditions to better shield your films from UV light.

By following these steps, you create a routine that not only preserves your films but also maximizes their performance over time. Regular maintenance isn’t just an extra task; it’s an investment in long-term reliability.

Why Choose APICAL® Polyimide Film

APICAL® Polyimide Film stands out due to its unique traits that cater specifically to high-demand industries like aerospace and electronics. Its ability to endure extreme conditions makes it especially popular. The thoughtful design ensures it meets the need for reliability and effectiveness. Choosing this film means selecting a solution that aligns with the requirements of demanding applications.

APICAL® Polyimide Film is valued for how it maintains its insulating and temperature-resistant features, even after regular use in harsh environments. Much of its appeal comes from the way it integrates seamlessly into a range of innovative solutions, ensuring that the final products meet expectations without compromise.

Keeping Your Polyimide Film in Top Shape

Summing up, maintaining polyimide film involves understanding discoloration causes, taking preventive measures, and knowing when correction or replacement is necessary. Regular maintenance routines support the longevity and quality of the film, and APICAL® ensures that industries have reliable, enduring options.

Maintain practices like proper storage, using protective coatings, and staying ahead of wear signs, to make sure your polyimide film performs its best. Extend the life of your films by making preservation a continual priority, encouraging consistent best practices and minimizing future issues. With this approach, you’re well-equipped to keep your materials in optimal condition.

To ensure your materials continue to perform at their best, explore APICAL® Polyimide Film options that can withstand challenging conditions. Our polyimide solutions are designed to meet the demands of various industries by maintaining durability and integrity. Discover more about our Apical Polyimide Film and how it can enhance your products today.