Selecting the Ideal Polyimide Film for Your Project

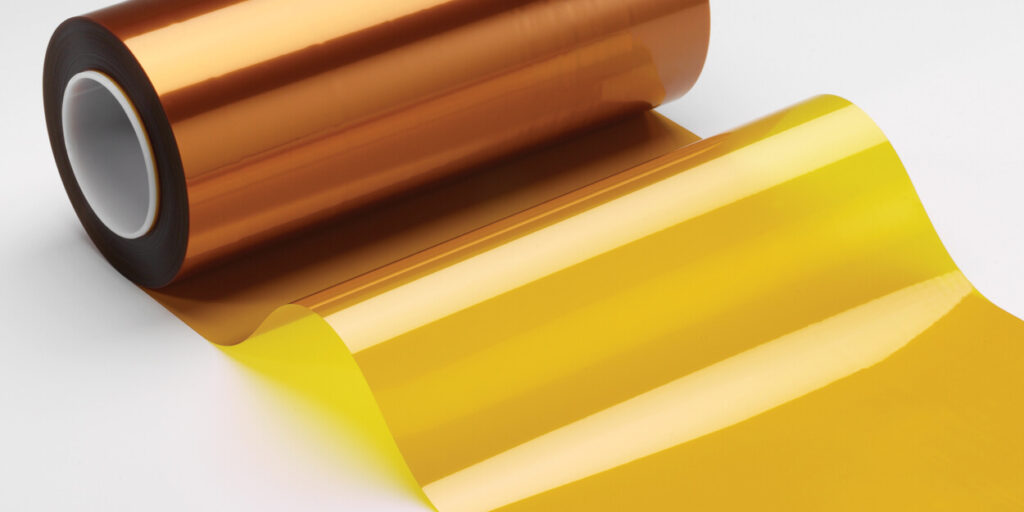

Selecting the right polyimide film for your project can make a significant difference in the performance and longevity of your work. Polyimide film is known for its outstanding heat resistance, electrical insulation, and chemical stability, making it a preferred choice in many industries. However, with various types and grades available, choosing the perfect one can seem overwhelming.

By carefully evaluating these aspects, you can ensure that the polyimide film you choose will meet the demands of your project efficiently. In the following sections, we will explore these considerations in detail, guiding you step-by-step to choose the right polyimide film for your project.

Understanding Polyimide Film Specifications

Key Properties to Look For

When choosing polyimide film, it’s important to know the key properties that make this material stand out. Polyimide film is known for its high heat resistance, which means it can withstand extreme temperatures without melting or degrading. This is crucial for applications where heat is a major factor.

Electrical insulation is another important property. Polyimide film acts as a barrier to electrical currents, preventing short circuits and electrical failures. It also offers excellent chemical stability, resisting damage from a variety of chemicals and solvents. This stability ensures that the film maintains its performance over time.

Different Grades and Types

Polyimide film comes in different grades, each designed for specific applications. For example, there are standard grades for regular use and high-performance grades for more demanding projects. Some types are more flexible, allowing for use in applications where bending and twisting occur frequently.

There are also variations in thickness and adhesive types. Thicker films provide better protection but may be less flexible. The type of adhesive used can affect both the performance and application of the film. Understanding these differences will help you choose the right type for your specific needs.

Assessing Your Project’s Needs

Application-Specific Requirements

Every project is unique, so it’s important to assess the specific requirements of your application. Think about what the polyimide film will be used for. If it’s for electronic circuits, you’ll need a film with high electrical insulation. For thermal management, a film with excellent heat resistance is crucial.

Consider the size and shape of the components you are working with. Flexible polyimide films are ideal for projects involving intricate shapes or tight spaces. If your project requires a lot of bending or twisting, make sure to choose a film that can handle it without breaking.

Environmental and Performance Considerations

The environment where the polyimide film will be used is also important. If the project involves exposure to harsh chemicals, choose a film with high chemical resistance. Look for films that can withstand UV radiation and weather conditions for outdoor applications.

Performance expectations should also be considered. Will the film need to endure high stress or pressure? Will it be exposed to moisture or extreme temperatures? Answering these questions will help you find a polyimide film that can meet the demands of your project.

By thoroughly understanding the specifications and assessing your project’s needs, you’ll be well-equipped to choose the right polyimide film, ensuring the success and longevity of your work.

Comparing Branded vs. Non-Branded Polyimide Film

Cost and Quality Differences

When selecting polyimide film, one important consideration is deciding between branded and non-branded options. Branded films, like those from well-known manufacturers, often come with a higher price tag. This is because you’re paying for the brand’s reputation, quality assurance, and sometimes added features.

Non-branded films can offer similar qualities at a lower cost. These films may not have the same rigorous testing as their branded counterparts, but they can still provide good performance. The key is to evaluate your project’s needs and decide if the extra cost for a branded product is justified or if a non-branded film will suffice.

Pros and Cons of Each Option

Branded Polyimide Film:

– Pros: Guaranteed quality, reliable performance, comprehensive customer support.

– Cons: Higher cost, potentially unnecessary features for basic applications.

Non-Branded Polyimide Film:

– Pros: More cost-effective, sufficient for standard applications.

– Cons: Variable quality, less customer support, potential lack of advanced features.

By weighing these pros and cons, you can effectively make an informed decision that balances cost and performance.

Making the Final Decision

Tips for Choosing the Right Film

Choosing the right polyimide film involves several key steps. First, clearly define your project’s requirements. Make a list of the essential properties the film must have, such as heat resistance, electrical insulation, and chemical stability.

Next, conduct thorough research on different films. Read product specifications, compare features, and look for customer reviews. If possible, request samples to test the film’s performance in your specific application. This hands-on evaluation can provide valuable insights.

Common Mistakes to Avoid

Avoid these common mistakes to ensure you select the right polyimide film for your project:

1. Ignoring Project Specifications: Always align the film’s properties with your project’s needs.

2. Overlooking Environmental Factors: Consider temperature, humidity, and chemical exposure.

3. Choosing Based on Price Alone: A cheaper film may lead to higher costs if it fails prematurely.

4. Skipping Sample Testing: Testing helps confirm if the film performs as expected.

By taking these tips into account, you can confidently choose the right polyimide film, ensuring your project’s success.

Find the Perfect Polyimide Film for Your Project with APICAL® Solutions

Selecting the appropriate polyimide film is crucial for any project’s success. By understanding the key properties, assessing your project’s specific needs, and comparing branded versus non-branded options, you can make an informed decision. Pay attention to the film’s specifications and the environmental conditions in which it will be used to avoid common mistakes.

Whether you’re working on an electronic device, an industrial application, or another project requiring durable insulation, choosing the right polyimide film ensures quality and efficiency. Don’t rush the decision; take the time to evaluate all factors involved.

For the right polyimide film options, consider APICAL® Polyimide Film. We offer a variety of high-quality films tailored to meet your project’s unique needs. Reach out to us today to find the perfect solution for your application.