Circuit Board Manufacturing Challenges and How to Solve Them

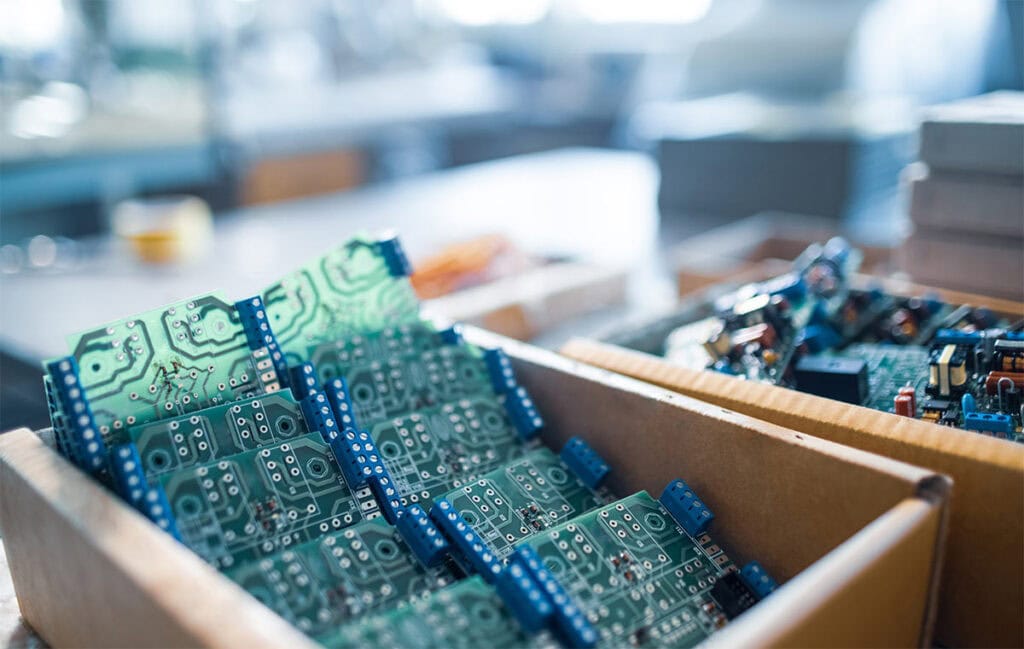

Circuit board manufacturing is a fascinating field but comes with its share of challenges. These tiny yet intricate pieces form the backbone of modern electronics, acting as essential layouts where connections are made, and components play their part in complex designs. However, issues during the component placement process can disrupt functionality, leading to setbacks, performance hiccups, or complete failures.

Addressing these issues is vital for businesses seeking to maintain quality and efficiency. Accurate placement of each component not only streamlines the manufacturing process but also ensures the reliability of the final product. Tackling these challenges reduces the risk of costly mistakes, saving both time and resources in the process.

Common Causes of Component Placement Issues

Numerous factors can interfere with component placement. One primary issue is misalignment due to improper machine calibration, akin to fitting puzzle pieces without lining them up. This frustration is mirrored in circuit boards when machines are not correctly calibrated.

Here are some frequent causes behind these placement problems:

- Misalignment Due to Machine Calibration: Machines need regular calibration to ensure precise movements and placements. A calibration drift can lead to components being off by even the tiniest margins, affecting the entire system.

- Inconsistent Solder Paste Application: The application of solder paste must be even and consistent. Any irregularity can cause components to sit unevenly on the board.

- Loose or Uneven Components: If components aren’t securely placed, they can tilt or move, resulting in poor connections.

- Dust or Debris on the Board Surface: Tiny particles might not seem like an issue, but on a circuit board, they can cause components to malfunction if not properly cleaned before placement.

By recognizing these common issues, manufacturers can take proactive steps to minimize them, ensuring a smoother production process and more reliable end products.

Techniques for Accurate Component Placement

Precision in circuit board manufacturing often relies on a few critical techniques. Here are effective methods to enhance component placement accuracy and minimize errors.

- Proper Machine Calibration:

Regular calibration of placement machines is crucial. This process ensures that machines work efficiently, positioning components exactly where they should be. Scheduling periodic checks and calibrations helps maintain precision. - Quality Solder Paste:

Using high-quality solder paste is essential. Not all pastes are made the same, and inferior products can lead to uneven application. Opt for reliable brands and consistent application methods to reduce the risk of uneven components. - Pre-Placement Cleaning:

Before placing components, ensure the board is free of contaminants like dust or debris. Even a speck can interfere with component placement, so a thorough cleaning routine is beneficial. - Automated Optical Inspection:

Investing in automated optical inspection (AOI) systems can catch misplacements early. AOI machines scan the boards post-placement, quickly identifying errors. Incorporating AOI within the process streamlines quality checks and minimizes manual inspections.

These techniques enhance precision and foster a smoother production process, reducing the likelihood of costly delays and ensuring product quality.

The Role of APICAL® Polyimide Film in Circuit Board Manufacturing

In electronics, every detail matters, and materials like APICAL® Polyimide Film play a significant role. This film supports circuit board manufacturing, helping keep everything in place and functioning optimally. Its insulation qualities add a layer of security, ensuring components are protected from excessive heat and electrical currents.

Additionally, polyimide film is reliable in demanding environments. Whether dealing with temperature fluctuations or physical stress during manufacturing, it holds up where other materials might falter. It acts as a bridge connecting different parts of the board, facilitating smooth electrical flow while guarding against potential vulnerabilities.

High-quality film enhances the overall durability of circuit boards, making them suitable for various applications from aerospace to electronics. The film’s capacity to provide consistent results underscores its value in this industry. By adopting reliable materials, the manufacturing process benefits from fewer disruptions and more consistent outcomes.

Regular Maintenance and Inspection Tips

Routine upkeep is crucial for successful circuit board manufacturing. Here are a few maintenance tips to keep everything working smoothly.

- Equipment Calibration: Keep machines in check with routine calibrations. Even the smallest drift can lead to errors, so frequent alignment checks are invaluable.

- Component and Board Inspection: Conduct regular inspections. Identify any anomalies early, like misaligned components or surface imperfections, to prevent potential breakdowns.

- Clean Environment: Maintain a dust-free, controlled workspace. It reduces the risk of contamination and ensures components fit and function as intended.

- Training Programs: Invest in continuous staff training. Keeping everyone updated with the latest practices and technologies ensures the team operates at peak efficiency.

Integrating these tips into a routine cultivates an environment where high-quality production is the norm, decreasing missteps and supporting smooth operations.

Maintaining Quality in Your Manufacturing Process

Crafting reliable and functioning circuit boards requires diligence and a proactive approach. Addressing component placement issues is key to preserving the integrity and functionality of electronic products. Ensuring precision through calibration, quality materials, and regular maintenance prevents small problems from escalating into costly errors.

Focusing on these practices strengthens the overall manufacturing process. Implementing these strategies assures a seamless transition from materials to the final product. By considering each step in the process, you foster an environment where quality isn’t just a goal but a standard.

To ensure your production lines produce consistently reliable circuit boards, consider integrating premium materials into your manufacturing process. Explore how APICAL® Polyimide Film supports industry standards by incorporating best practices for circuit board manufacturing. Discover how the right materials can drive your quality control efforts forward.