Enhancing Printed Circuitry with Flexible and Durable Materials

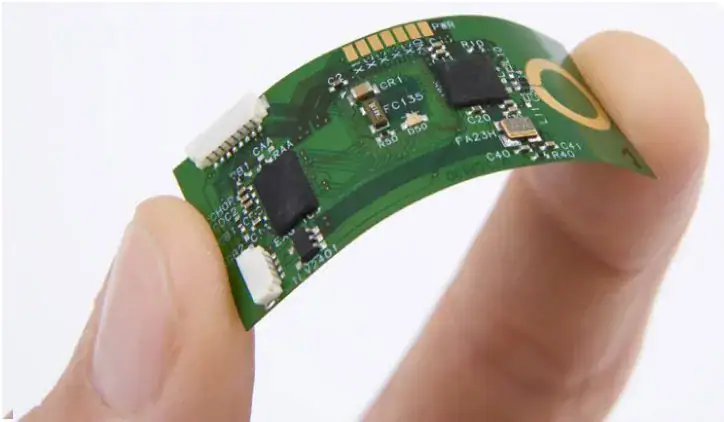

Printed circuit boards (PCBs) are essential components in electronics, enabling connections between various parts of a device. As technology evolves, the demand for flexible printed circuitry has increased. Flexible circuits allow for compact and lightweight electronic designs, making them suitable for modern applications like smartphones, wearable devices, and medical equipment.

Flexible circuits need materials that can bend and twist without breaking. Traditional rigid materials can’t meet these demands, leading to the development of flexible materials like polyimide films. These films offer the needed flexibility and can handle the stresses of bending and movement.

APICAL® Polyimide Film is one such material that stands out in the field of flexible printed circuits. It offers the flexibility required for intricate designs while providing reliable performance through its heat-resistant and electrically insulating properties. By using APICAL®, manufacturers can create more durable and efficient circuits, meeting the demands of today’s advanced electronic devices.

Why Flexibility is Crucial in Printed Circuitry

Modern electronics demand flexible materials due to the compact and intricate designs found in many devices. Flexible printed circuitry allows for more design freedom, enabling the creation of products that are lighter and have a smaller footprint. This flexibility is essential for devices like smartphones, wearables, and medical instruments, where space is limited.

One of the main challenges in printed circuitry is maintaining performance while allowing for bending and movement. Traditional rigid boards can’t handle these demands and may break or lose functionality when bent. Flexible materials, like polyimide films, can bend and twist without damage, ensuring consistent performance.

Engineering around flexibility also helps address issues like thermal expansion and contraction, which can lead to circuit failure. Flexible materials can accommodate these changes, reducing the risk of mechanical stress and extending the lifespan of the circuit. By leveraging flexible materials, manufacturers can create more reliable electronics that meet the varied needs of today’s technology.

Key Benefits of Using APICAL® Polyimide Film in Flex Circuits

APICAL® Polyimide Film offers numerous benefits crucial for flexible circuit applications. These benefits include heat resistance, excellent electrical insulation, and dimensional stability.

-

Heat Resistance

- APICAL® Polyimide Film can withstand temperatures up to 500°F. High heat resistance ensures the film remains stable and performs well even under extreme conditions. This property is essential for preventing damage and ensuring the longevity of the circuits.

-

Electrical Insulation

- The film provides excellent electrical insulation, reducing the risk of short circuits and electrical failures. Strong insulation maintains the circuit’s integrity and ensures consistent performance, making the electronics safer and more reliable.

-

Dimensional Stability

- APICAL® Polyimide Film offers excellent dimensional stability, meaning it does not shrink or expand much with temperature changes. This stability ensures that the circuits remain precise and function correctly, preventing any misalignments or faults due to thermal variations.

These benefits directly translate to improved reliability and performance of flexible circuits. By using APICAL®, manufacturers can ensure their circuits perform well in varied environments, endure high temperatures, and provide consistent electrical insulation. This makes APICAL® a valuable material for creating durable and efficient flexible circuits.

Comparing APICAL® and Kapton® in Flex Circuit Applications

When comparing APICAL® and Kapton® in flex circuit applications, several key differences emerge. Both materials are well-regarded in the industry, but APICAL® Polyimide Film provides unique benefits that can make it a preferred choice in certain scenarios.

- Flexibility and Durability: APICAL® Polyimide Film boasts excellent flexibility and durability, which makes it highly suitable for repeated bending and movement. Kapton® also offers flexibility but may not hold up as well under constant flexing, especially in more demanding environments.

- Thermal Performance: Both films are heat-resistant, but APICAL® maintains dimensional stability better during temperature cycling. This stability is crucial in applications where the circuit will experience rapid temperature shifts, reducing the risk of mechanical failures.

- Electrical Insulation and Chemical Resistance: APICAL® provides strong electrical insulation, protecting against short circuits and maintaining performance over time. It also exhibits better chemical resistance, shielding the circuitry from harsh chemicals that can cause degradation. Kapton® is strong in these areas but may not match the overall resistance profile of APICAL®.

- Preferred Scenarios: APICAL® is often chosen for applications requiring high reliability and endurance, such as medical devices and advanced electronics. Its superior performance during thermal cycling and chemical resistance makes it suitable for these demanding uses.

Future Trends in Printed Circuit Technology

Printed circuit technology continues to evolve, driven by the need for more compact, efficient, and reliable electronics. Several emerging trends are shaping this field, with flexible circuits playing a pivotal role.

- Wearable Technology: Flexible circuits are critical in wearable devices, from fitness trackers to medical monitors. Their ability to bend and conform to various shapes makes them ideal for devices worn on the body. As this sector grows, the demand for high-performance materials like APICAL® will increase.

- Internet of Things (IoT): The IoT revolution is creating a need for flexible, durable circuits that can be embedded in everyday objects. These circuits must withstand varied environments and conditions, making the properties of APICAL® Polyimide Film highly desirable.

- Advanced Manufacturing Techniques: Techniques such as 3D printing and additive manufacturing are being used to create more complex and efficient circuits. Flexible materials like APICAL® enable these new manufacturing methods, leading to greater innovation and efficiency in electronic design.

- Miniaturization: As electronics continue to shrink in size, the need for materials that can maintain functionality in small, flexible designs is paramount. APICAL® helps meet this demand through its dimensional stability and reliable performance.

APICAL® Polyimide Film is well-positioned to be at the forefront of these trends, providing the necessary flexibility, durability, and performance for the next generation of printed circuit technology.

Enhance Printed Circuitry Performance with APICAL® Polyimide Film

Maximizing flexibility and reliability in printed circuitry is essential for modern electronics. APICAL® Polyimide Film offers significant advantages, such as heat resistance, strong electrical insulation, and excellent dimensional stability. These properties make it an ideal material for creating durable and efficient flexible circuits. Therefore, it is evident that APICAL® is valuable in industries where performance and reliability are critical, including medical devices, wearables, and advanced electronic applications.

The differences between APICAL® and Kapton® show that APICAL® is uniquely suited for applications requiring superior flexibility, thermal stability, and chemical resistance. Moreover, emerging trends like wearable technology, IoT, advanced manufacturing, and miniaturization highlight the importance of high-performance materials like APICAL®.

To explore how APICAL® Polyimide Film can enhance your printed circuit designs, check out our offerings. Discover the potential of flexible printed circuits and how our products can meet your specific needs.