How Polyimide Film Enhances the Performance of Pressure Sensitive Tapes

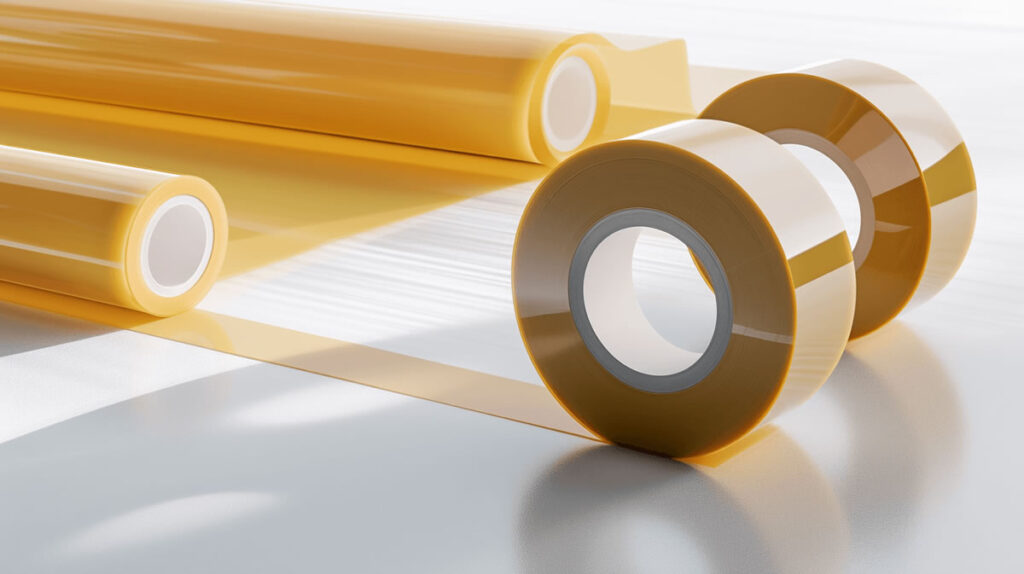

Polyimide film has been steadily transforming the realm of pressure-sensitive tapes, offering a variety of uses across different industries. Made from a high-performing polymer, this film is known for its exceptional durability and ability to withstand extreme temperatures, up to 500 degrees Fahrenheit. This makes it invaluable in environments that experience high heat or require reliable electrical insulation.

Pressure-sensitive tapes made from polyimide film are extensively used in electronics, aerospace, and automotive sectors. These tapes help in insulating wiring, protecting sensitive components, and even sealing connections. The robust nature of polyimide film ensures that these tapes perform efficiently, no matter the conditions they are exposed to.

The unique properties of polyimide film, such as heat resistance, chemical stability, and flexibility, make it a go-to material for pressure-sensitive tapes. Unlike other tapes, polyimide-based tapes do not degrade easily, ensuring long-lasting performance and reliability. This article will delve into how polyimide film, especially APICAL® Polyimide Film, plays a critical role in revolutionizing pressure-sensitive tapes, driving advancements and securing a dependable future for these essential industrial tools.

Understanding Polyimide Film in Pressure Sensitive Tapes

Polyimide film is a high-performance polymer known for its robustness and ability to endure extreme conditions. It is typically used in environments that experience high temperatures and require reliable electrical insulation. This film is characterized by its yellowish color and flexibility, which makes it suitable for various industrial applications.

In pressure-sensitive tapes, polyimide film is crucial for creating a reliable adhesive tape that can withstand demanding conditions. These tapes are designed to stick to surfaces when pressure is applied, without the need for heat or water activation. Polyimide film-based tapes are widely used in the electronics, aerospace, and automotive industries due to their impressive properties.

The film acts as a durable backing material that supports the adhesive layer of the tape. This backing material needs to resist tearing, stretching, and degradation when exposed to environmental factors such as heat, chemicals, and moisture. Polyimide film excels in these areas, ensuring that the tape remains effective in protecting and insulating various components and surfaces.

Benefits of Using Polyimide Film for Pressure Sensitive Tapes

Polyimide film offers several benefits that make it ideal for use in pressure-sensitive tapes. These advantages greatly improve the performance and durability of the tapes in various applications.

1. Heat Resistance: Polyimide film can withstand temperatures up to 500 degrees Fahrenheit. This makes it perfect for applications that involve high heat, such as in electrical insulation or aerospace components.

2. Flexibility: The film’s flexibility allows it to conform to irregular surfaces without breaking or losing adhesion. This feature is especially useful in wrapping wiring or sealing connections in tight spaces.

3. Insulation: Polyimide film provides excellent electrical insulation. This is crucial in preventing short circuits and protecting sensitive electronic parts from electrical interference.

These benefits translate to better performance in real-world applications. For instance, in the electronics industry, the heat resistance of polyimide film ensures that components stay protected, even when devices heat up. In aerospace, the flexibility and insulation properties help in maintaining the integrity of electrical systems under extreme stress and varying conditions.

By integrating polyimide film into pressure-sensitive tapes, industries can achieve higher reliability and longevity in their products. This, in turn, reduces the need for frequent maintenance and replacements, saving time and resources.

APICAL® Polyimide Film vs Kapton®: Key Differences

When comparing APICAL® Polyimide Film and Kapton® by DuPont, several key differences emerge that influence their use in pressure-sensitive tapes. While both materials share the core benefits of polyimide films, such as heat resistance and electrical insulation, there are specific attributes that set them apart.

One important difference lies in their adhesive properties. APICAL® Polyimide Film often features custom adhesive solutions tailored to specific industrial needs. This allows for better adherence in environments where standard adhesives might fail. Kapton®, although robust, may not always offer the same level of versatility in adhesive options.

In terms of durability, APICAL® Polyimide Film is known for its superior chemical resistance. It performs better in harsh chemical environments, making it more suitable for industries where exposure to aggressive chemicals is common. This characteristic ensures that the tape remains effective and does not degrade prematurely.

Another factor is thermal stability. While both films can withstand high temperatures, APICAL® Polyimide Film often exhibits better performance in environments with rapid temperature fluctuations. This makes it more reliable for applications involving repeated thermal cycling, such as in aerospace and automotive industries.

These distinctions highlight why some industries opt for APICAL® Polyimide Film over Kapton®. Its specialized adhesive options, enhanced chemical resistance, and superior thermal stability provide reliable solutions for demanding applications, ensuring that critical components remain protected and functional.

Future Innovations in Polyimide Film for Pressure Sensitive Tapes

Recent advancements in polyimide film technology are opening new possibilities for pressure-sensitive tapes. As the need for more durable and efficient materials grows, innovations in polyimide film continue to evolve, offering promising changes for industrial applications.

One exciting development is the inclusion of advanced adhesive formulations. These new formulations enhance bonding strength and ensure compatibility with a wider range of surfaces. This advancement enables pressure-sensitive tapes to be more versatile and effective in challenging conditions.

Another area of innovation is the integration of enhanced thermal management features. Researchers are working on polyimide films that can better dissipate heat while maintaining insulation properties. This makes the tapes more efficient in high-heat environments, reducing the risk of overheating and improving reliability.

Looking ahead, the future of polyimide film may include self-healing properties. Scientists are exploring materials that can repair themselves when damaged, extending the lifespan of tapes and reducing maintenance needs. This potential breakthrough could revolutionize the use of pressure-sensitive tapes in various industries, ensuring long-term performance with minimal intervention.

Overall, these advancements indicate a bright future for polyimide films. The continual improvements in adhesive strength, thermal management, and self-healing capabilities suggest that polyimide films will play an increasingly important role in enhancing the performance and reliability of pressure-sensitive tapes.

Enhance Your Pressure Sensitive Tapes with APICAL® Polyimide Film Solutions

Polyimide film has proven to be a vital component in the development and enhancement of pressure-sensitive tapes. With its unique combination of heat resistance, flexibility, and insulation properties, it provides a reliable solution for various industrial applications. The differences between APICAL® Polyimide Film and Kapton® highlight why certain industries prefer APICAL® for their specific needs, ensuring dependable performance even under intense conditions.

The ongoing advancements in polyimide film technology point to an exciting future. Innovations in adhesive formulations, thermal management, and potential self-healing properties will likely expand the application and effectiveness of these tapes. These improvements will not only benefit current uses but also open up new possibilities for the future.

For industries looking to enhance the performance and durability of their pressure-sensitive tapes, polyimide film stands out as a robust choice. To explore how APICAL® Polyimide Film can meet your needs, visit our website and discover a range of products designed to tackle your toughest challenges.